Project Description

Punching Service

SERVICE INFORMATION

Our punch processes sheet sizes up to 2500mm x 1250mm and 3mm thick steel, or 4mm thick aluminium. We have an extensive tool library, with countersinking tools, forming tools, dimple tools and embossing tools, and regularly invest in new tooling to meet our customers’ requirements. Our embossing services are popular with customers who would require the ability to identify their parts in production, or for embossing their logos onto their products.

Sheet Metal Punching

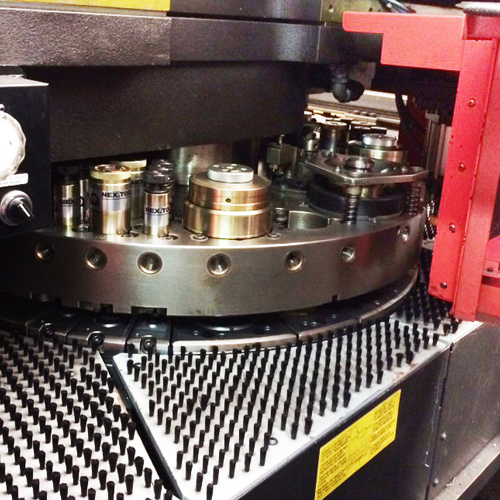

Sheet metal punching is performed with the leading technological equipment of the Amada brand. Forming tools for sheet metal punching are preferred because they enable the user an easier installation of products and thus faster and more efficient manufacturing. Our expertise and set of tools is constantly being upgraded, therefore, we are constantly confirming the status of the great provider of sheet metal punching services.

The main characteristics that define sheet metal punching are:

CNC program which enables quick response to changes in customer needs

Up to 58 punching tools (per program), which can be complemented by multi-digit tools (multi-tools)

Sheet metal punching with accuracy of up to 0.1 mm

Processing of material in plates for dimensions of up to 1500x3000mm

Processing of material with the thickness of up to of 3mm, for stainless steel up to 2mm